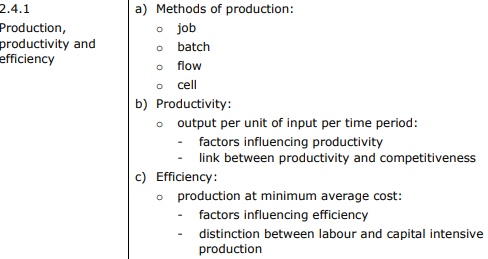

Production:

Taking the 'factors of production' and turning them into 'products'.

Job, batch,flow and cell production:

Job production involves making a single product at a time.

Lets make a unique talking dog:

Because the numbers produced are small this method of production tends to be labour intensive.

Batch production:

Production is divided into a number of operations.

A particular operation is carried out on all products in a batch.

Flow production:

Cell production:

Cell production is a form of team work where the entire process of production is split into small groups called cells.

Each 'cell' is responsible for a complete unit of work.

Once this work has been completed it moves to the next 'cell'.

Each 'cell' checks the quality of its work.

More here.

More details on methods of production here. (Scroll down the page.)

You need to learn two advantages and two disadvantages of each method.

Labour productivity: