Can you describe what this chart shows?

If you are not sure watch this video:

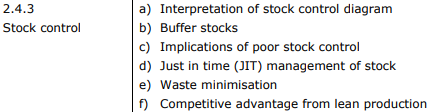

The cost of holding inventory (stock in costs) involves:

Warehousing costs such as rent, utilities and salaries.

Financial costs such as opportunity cost.

Inventory costs related to perishability, shrinkage (theft) and insurance.

Buffer stock

The minimum level of inventory (stock) a business aims to hold.

Implications of poor stock control:

1. Stock out costs (Out of stock costs)

Stock out costs are the costs associated with the lost opportunity caused by the exhaustion of the inventory.

2. Holding excess stock.

Less working capital would be available within the firm.

Costs of storage, insurance and security.

A risk that the stock could become obsolete, damaged or 'expired'.

Just in time production aims for near zero levels of buffer stock.

Stock levels of raw materials, components, work in progress and finished goods can be kept to a minimum.

This requires a carefully planned scheduling and flow of resources through the production process.

More on JIT here.

Waste minimisation.

This is a key element of lean production.

Waste is anything that adds an additional cost.

Lost time is a major cause of waste.

Damaged or returned goods should be kept to a minimum.

Competitive advantage from lean production.

What competitive advantage would the 'leanest' European car manufacturer have over its rivals?

More here.