Capacity utilisation measures the extent to which a business is using its production potential.

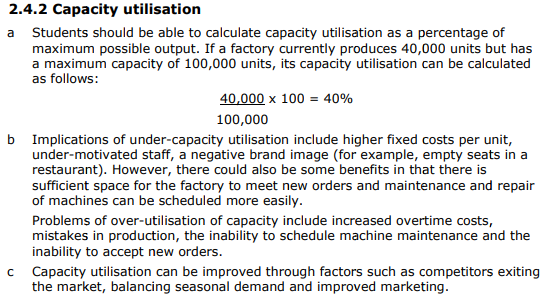

Capacity utilisation can be defined as - the percentage of total capacity that is actually being achieved in a given period

The Problems Of High Capacity Utilisation:

100% capacity utilisation is not always a positive thing for businesses.

By operating at maximum capacity for long periods of time the business might experience the following issues:

No time for the maintenance of machinery.

Increased overtime costs

Unable to accept additional orders.

Harder to maintain quality standards.

The Benefits of High Capacity Utilisation:

· Increased job security and motivation.

· Improved profitability.

Thorntons Chocolate operate three eight hour shifts in the run up to Valentines day:

Operating at low levels of capacity utilisation bring

with them their own problems:

Higher unit costs that may mean either lower profit

margins or higher costs for the consumer.

margins or higher costs for the consumer.

Motivational issues for staff e.g. employee boredom.

Possible Cause of Under Utilisation:

· New competitors entering the market

· Changing tastes and fashions in the market.

· Seasonal factors.

· Over-investment in fixed assets.

Possibilities that under capacity utilisation brings:

Sufficient space in the factory to meet new orders.

Maintenance and repair of machines is easier to

organise.

organise.